Simulators, or sims, are multimillion-dollar pieces of aviation technology perched atop hydraulic legs, giving real motion to manoeuvres made in a fully replicated flight deck. Newly qualified cadets will use a virtual flight to learn their aircraft before taking to the skies, and they’re also where pilots get tested twice a year with safety scenarios to update their skills and licences.

Inside the Boeing 747-8F simulator at Cathay Pacific’s Hong Kong headquarters, Mark Hoey, the airline’s General Manager Operations, sits in the left-hand seat. In front of us, video screens that act as windows show Ted Stevens International Airport in Anchorage, Alaska, with parked planes and airport vehicles buzzing about. It is startlingly realistic.

‘The visuals are a blend of Google Earth satellite imagery mixed with technology from video-game producers as you get close to the ground,’ explains Hoey.

Cathay Pacific used this virtual flight to Anchorage in its work to design a computerised approach into a US airport and get it approved by the Federal Aviation Authority (FAA). It’s the first overseas airline to accomplish this aviation feat.

Cathay Pacific Cargo crosses the Pacific to link Hong Kong to a network spanning the Americas, with all inbound and outbound flights stopping in Anchorage to take on fuel. This enables the fleet of 21 Boeing 747 freighters – 14 of which are new, state-of-the-art 747-8Fs – to carry more cargo.

Surrounded by snow-capped mountains and beset with challenging weather – especially in winter – Ted Stevens International Airport has three runways that can be used from either end depending on wind direction. It’s always preferable to land aircraft into wind for greater control and a slower speed on the runway so the plane can stop more quickly. This is essential when snow and ice ‘contaminate’ runways, increasing the distance needed for cargo-laden aircraft to come to a halt.

(Click to expand)

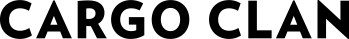

All runways at Anchorage are fitted with instrument guidance that work with aircraft systems to offer an automated ‘instrument approach’ to be flown using the autopilot. The exception is when the wind blows from the west, putting runways 25L and 25R into play. They are numbered after their bearing, with the L and R standing for ‘left’ and ‘right’ to differentiate the parallel strips.

These runways pose a challenge for pilots. ‘There is no instrument guidance to runways 25L and 25R – it is a wholly visual approach,’ explains Hoey. ‘This means there is no data that can be entered into the flight management computer, so the aircraft must be flown manually using visual references – which is not always ideal given Alaska’s weather.’

Although westerly winds usually come in milder summer weather, there are still difficulties with the approach to 25L and 25R, particularly at night when the water and wilderness surrounding Anchorage provide little light for visual reference. Hoey says: ‘What we found from our own safety data was that crew would rather land using the maximum permitted tailwind on the opposite runways rather than this more challenging approach, especially at the end of a long flight when they are tired.’

So, Cathay Pacific started work on a computerised approach, with the support of the FAA and an expert navigational data supplier. ‘Once they realised this idea was driven by our safety information, the FAA was really supportive,’ says Hoey.

But building a new approach is not as simple as drawing some lines on a map. It has to fit the performance of the aircraft in terms of turn radius and speed, and also take in considerations on the ground to satisfy risk and environmental concerns. The process took a good year or so, and the sim tested each iteration of the data ahead of a real-world test and subsequent approval.

On our day in Cathay Pacific’s sim, Hoey demonstrates the FAA-approved approach and the technology that helped in its development. Sitting at a control console behind the pilots’ seats, he sets weather conditions and the weight of the aircraft, which has a bearing on performance. From this console, emergency and meteorological scenarios are entered to test pilots during virtual flight training sessions. We’re flying heavy at 320 tonnes for this simulation, and the approach will run in both daytime and nighttime conditions, with the weather set to fair so we can see where we’re going.

‘Today is a lovely clear day – blue skies, which is what Anchorage can be like in summer,’ Hoey says. We’re waiting at the end of the runway to take off to a point some 5,000 feet above the icy waters of Cook Inlet, where air traffic control at Anchorage vectors aircraft to start their final approach.

Hoey pushes the four throttle levers forward, and our virtual flight starts to thunder down the runway as the sound of four engines increases in pitch. With a flick of a ‘secret’ switch on a panel above his head, everything shuts down and he goes back to the control console to turn down the volume – the flight deck is ordinarily a headset environment. We then resume the take-off run and after the computer shouts ‘V1!’, the sim flight is in the air. Within minutes, we have a view of 5,000 feet above Cook Inlet and are ready to begin the approach.

‘We start over Cook Inlet heading for the mountain range straight ahead, and we make our descent with the airport on our left,’ says Hoey. The airport is highly visible through the ‘windows’, as the intensity of its lights were turned up using the sim’s control panel.

While descending, we make a left turn and fly below the peaks of the mountains. About five miles from them, we turn away and keep the mountain range on our right. Then it’s on to the next visible landmark, the Seward Highway. ‘It’s as if the right wing flies down the highway,’ says Hoey.

The highway serves as a boundary because to its right is another airport for light aircraft, with a lot of general aviation traffic that must be avoided. We keep in close and pass over an industrial zone in the city. ‘It’s really cool as it’s a curved approach all the way in,’ says Hoey. ‘We go wings level at only 800 feet for 25L and at just 400 feet for 25R, where we’re landing now because the runways are staggered. Then we switch off the autopilot and make a visual and manual landing from that point.’

The sim calls out the altitude. At ‘500!’ we’re still in the final left turn that starts at 1,000 feet. As the wings straighten, we hear ‘400!’, and there’s the runway. ‘Once the wings are level, we train the crew to assess the situation, and if it’s good they disconnect the autopilot and land straight ahead,’ says Hoey.

He disconnects the autopilot, which causes a siren to briefly sound, and then he pushes the throttles forward. We start climbing again and return to the starting point of the approach. Once back in position, Hoey goes to the control console to turn day into night. The mountainous terrain becomes invisible to the eye, and there are very few lights as we look to where the instruments indicate the mountains are.

‘Say it’s nighttime and there’s low cloud cover at 3,000 feet – you have to navigate and interpret things visually,’ says Hoey. ‘That’s a big ask at the end of a long flight, and if the winds are from the west they’re quite strong, so you could be bouncing around as well.’

Despite the change in conditions, the sim locks into the approach again, and soon we turn towards the lights of the runway. ‘I guess I better land it this time,’ says Hoey. The computer calls out ‘1,000’, then ‘500.’ The wings are level, and after hearing ‘400’, Hoey says: ‘I disconnect the autopilot, and I’m now manually flying the aircraft.’

The computer continues to count down the altitude – ‘50, 40, 30, 20, 10’ – and then the virtual flight touches down softly. ‘The beauty of this approach is that it’s repeatable again and again, and the aircraft is always perfectly aligned for the pilots to take over,’ says Hoey. ‘It’s a fantastic job, every time.’ And it’s a fantastic machine that demonstrated this approach.