It’s rare for the world’s press to take such a fervent interest in the air cargo industry. Yet the anticipation for a vaccine to bring the COVID-19 pandemic under control is increasingly urgent – and now the details of temperature-controlled air cargo are making regular news appearances.

When vaccines are finally released, the challenge to the industry will be huge. IATA has estimated vaccine distribution will require the equivalent of 8,000 Boeing 747s, and while some feel this may be slightly exaggerated – as much of the task will fall to cross-continental road transport – the scale of the logistical challenge for air cargo is undeniably daunting. The global population is 7.8 billion, and a number of the vaccines in development will require two injections. Then there are the special requirements to consider, with some vaccines requiring storage and transport temperatures far lower than the normal range of conventional life-science shipments.

‘Safely delivering COVID-19 vaccines will be the mission of the century for the global air cargo industry,’ said IATA Director General and CEO Alexandre de Juniac. ‘But it won’t happen without careful advance planning.’

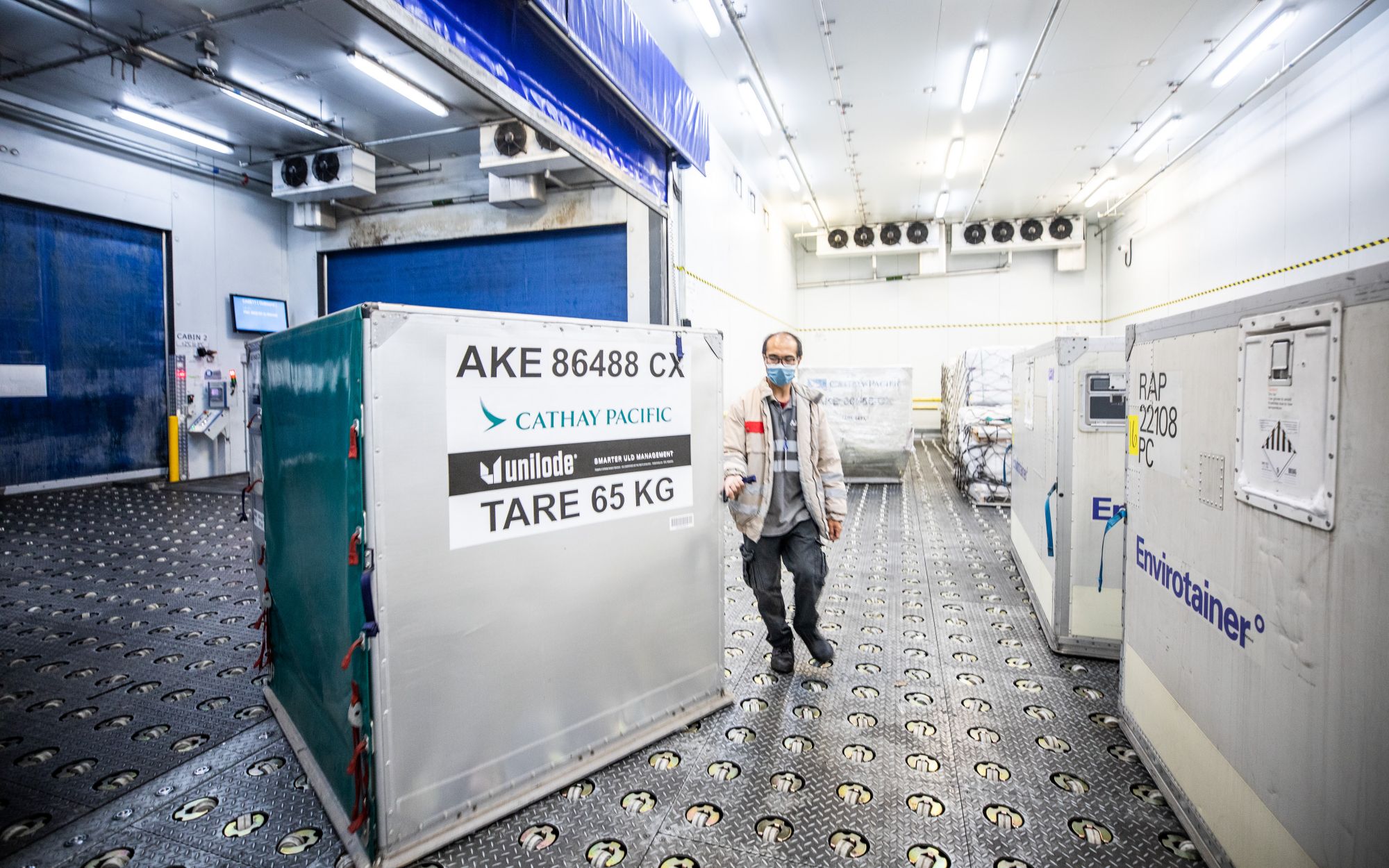

He was speaking in September, but that ‘careful advance planning’ was already well underway at Cathay Pacific Cargo, thanks to a vaccine task force that had previously been established. Urgent and pharma shipments are part of Cathay Pacific Cargo’s proven product range through Pharma LIFT and Priority LIFT, but the unprecedented scale of the vaccine uplift has required plenty of additional problem-solving across commercial and operational channels.

The first meeting, chaired by GM Cargo Commercial George Edmunds, brought together representatives from the Commercial, Product, Revenue Management (which looks after inventory), and Service Delivery teams, as well as managers from the Cathay Pacific Cargo Terminal. Subsequent meetings involved Cargo Managers from outports, especially those close to vaccine manufacturing sites. ‘They are our eyes and ears,’ says John Cheng, Head of Cargo Marketing and Products.

It quickly became clear that such a colossal task would need a bespoke solution. Cathay Pacific Cargo’s Vaccine Solution – draws on the best of Pharma LIFT and Priority LIFT, and adds more – including guaranteed priority upload for shipments and the accelerated roll-out of Ultra Track, the new name for the next-generation track-and-trace system that Cathay Pacific Cargo has been trialling over the past 12 months or so.

Ultra Track is a multi-dimensional tracking and data-logging system that uses low-energy Bluetooth transmitters, placed within individual boxes in a shipment, to record and transmit GPS position, temperature, vibration and humidity in near real-time, making it ideal for temperature-sensitive and fragile shipments. It’s not ready to roll out across the entire network in one go, but its phased introduction will focus on markets where the vaccine manufacturers are situated and the destinations where the vaccines are being sent.

The system will work in tandem with the newly established Operations Control Centre based in Hong Kong. Working in shifts, the team monitors shipments 24/7, and can take proactive steps to intervene should any cargo start to experience temperature excursions, delays, equipment malfunction or damage on the ground.

The Operations Control Centre adds a new layer of assurance for customers. ‘It will be staffed by a team of cargo operations professionals to ensure that shipments have the highest level of care,’ says Frosti Lau, GM Cargo Service Delivery.

That’s vital for the vaccine shipments. ‘The high value of the vaccines before they become widely available is a risk factor at a corporate level,’ explains Cheng. And the consequences of something going wrong are very serious in health and financial terms. ‘Most of the specialist forwarders we have contacted are very interested in the Ultra Track product,’ he adds.

This is in addition to the assurance of Cathay Pacific’s IATA CEIV Pharma accreditation, which was recently recertified – as was the CEIV Pharma accreditation of Cathay Pacific’s ground partners and subsidiaries at Hong Kong International Airport, including Cathay Pacific Services Ltd (CPSL), which manages the Cathay Pacific Cargo Terminal, and ground-handling company HAS.

Another reason a dedicated product is needed is to solve some of the practical challenges that the vaccine shipments throw up. For example, vaccines requiring a shipping temperature far below standard life-science shipments bring into play a delicate balancing act between the amount of dry ice required to maintain the correct temperature of a container, and the number of containers that can be carried on each flight.

‘There are operational limits on how much dry ice we can uplift,’ explains Alex Leung, Cargo Products Manager. Dry ice generates carbon dioxide as it sublimates, and although it’s inert, it ticks some dangerous goods boxes, especially on aircraft carrying passengers. But the less dry ice that is carried to maintain low temperatures, the fewer specialist cooltainers that can be uplifted. That’s a problem as both quantity and quality matter.

‘We have been in touch with Boeing and Airbus to review the dry ice limits,’ says Kevin Fung, Head of Cargo Global Operations. ‘There are even limits as to how much we can carry on freighters, albeit they are more generous limits. There has been progress, especially on the Airbus A350 and aircraft with limited numbers of passengers onboard, but it also depends on the ventilation systems in place on the aircraft.’

The other issue relates to the flow of the cooltainers. Cathay Pacific Cargo has operating partnerships with five leading suppliers, but the origins and destinations of the vaccine shipments are different to regular pharma traffic. ‘The logistics are tricky,’ says Alex Leung. ‘We will need to send empty containers back to origin to collect more vaccines as soon as possible, occupying valuable space on the return journey; so this is one-way traffic and it’s quite imbalanced.’

Ordinarily cooltainers, which can’t fold down to occupy less space, would go back to their base as and when space became available on return flights. But now they will need to be returned urgently to distribute more vaccines.

These considerations necessitate the close examination of schedules, working with forwarders to see what the potential trade lanes are, negotiating deals that factor in such issues and working with container suppliers to maximise traffic in a short period of time.

It’s a small detail that characterises the big challenge ahead, but as Edmunds says: ‘We are ready to play our part.’