The safe delivery and transfer of COVID-19 vaccines is essential if the world is to reopen and break the chains of the pandemic. The Cathay Pacific Cargo Terminal (CPCT), operated by wholly-owned subsidiary Cathay Pacific Services Ltd (CPSL), has been refining its processes to offer a speedy, priority service while maintaining all the temperature-sensitive protocols. This means vaccines will be stored in a cold room within an industry-leading 42 minutes from the plane arriving without breaking the cool chain, or ready for direct release for delivery into Hong Kong. As it stands, CPCT can handle 6.6 million doses of vaccine a day, building to around eight million by the end of the year.

There are many aspects to the vaccine shipment process. Here’s a step-by-step guide to the journey, from when an aircraft touches down with a vaccine shipment for import or transhipment.

Priority parking

Freighters with vaccine shipments onboard will be parked directly outside, or as close as possible, to the Cathay Pacific Cargo Terminal to minimise towing times and exposure to the unsheltered environment. Shipments on cargo-only passenger aircraft will mostly arrive at passenger terminal gates, but priority unloading and towing will ensure that this adds little to the total transfer time.

First off

All vaccine shipments will be given priority unloading status on arrival. Vaccine cooltainers will be positioned close to aircraft doors to make unloading quicker. According to CPSL’s timings, the unloading process will take 12 minutes.

Ready to tow

Active containers will be towed immediately to the terminal upon unloading.

Passive cooltainers will first be loaded into thermal dollies then towed to CPCT, ensuring 100 per cent temperature protection. There are 29 thermal dollies available for use, which can operate in a temperature range of -20°C to +20°C. They are capable of holding two AKE-size ULDs or one pallet.

Checking in at the terminal

On arrival at the airside reception area, the containers are scanned and either loaded into the automated Materials Handling System (MHS), the automated cargo transfer system, which will take transhipment containers straight into the suite of cold rooms on the fifth floor, or release them for collection.

Quick release for Hong Kong imports

Vaccine shipments will be available for release and pick-up within 15 minutes of arriving in the terminal. CPSL has worked with the Airport Authority and government departments to smooth the customs clearance process with paperwork ahead of the flight arriving. There may be delays if information is not available to customs ahead of arrival, or if an on-site inspection is required. Trucks can back into a dedicated loading bay close to the airside reception area on the ground floor of the terminal to further reduce towing times.

Cold box storage

For shipments sharing the same container that need to be broken down, recently installed cold boxes can hold individual boxes ahead of collection. CPSL has installed these temperature-controlled devices to maintain the cool chain within the terminal, as part of its efforts to offer the best and most precise temperature-sensitive service.

Tarmac transfers

For shipments on shorter connections that do not allow for transfer in and out of the CPCT, shipments may be left on the tarmac in thermal dollies and under shade shelters. Data on temperature and location will be collected by CPSL staff using its in-house tracking system, while shipments using Cathay Pacific Cargo’s Ultra Track will be transmitting data. This means it will be instantly flagged if there’s a need to replenish any dry ice or charge active container batteries.

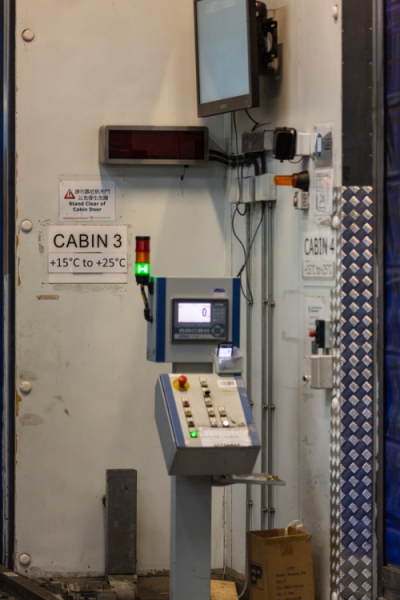

Cold room transfers

Upon arrival in the cold room suite, containers will be transferred to the room with the most appropriate temperature range for the shipment. Dry ice can be replenished, and there are multiple charging points for active cooltainers. Containers are stored away from the rapidly opening and shutting automated doors to keep their temperature more constant. Shipments will be dispatched from the terminal ahead of their onward flight.